We use no natural gas

The best materials were used for the construction of our new business premises (in 2014). Good insulation means our energy consumption is already very low. The installation of a heat pump and the use of green power mean that our building is 100% energy neutral. In the winter we get heat from sources in the ground. In the summer the heat pump recharges the underground sources with heat. That also means that we have a beautifully cool office in the summer.

We drive on hydrogen

Our second hydrogen-powered company car was delivered in January 2020. We are pleased to be an ambassador for this environmentally-friendly fuel. Finding refuelling stations (in time) is still a challenge occasionally, but we are happy to cope with that slight inconvenience.

We call with Fairphones

Fairphone manufactures mobile phones and strives for handsets with 100% responsibly produced components and materials. Hence Fairphone obtains its cobalt, an important raw material for mobile phones, exclusively from slavery-free mines. Every handset has a modular construction. The user can order every part and replace it themselves. It may not be the coolest phone, but a Fairphone does last much longer this way. See also: www.fairphone.com/en/story

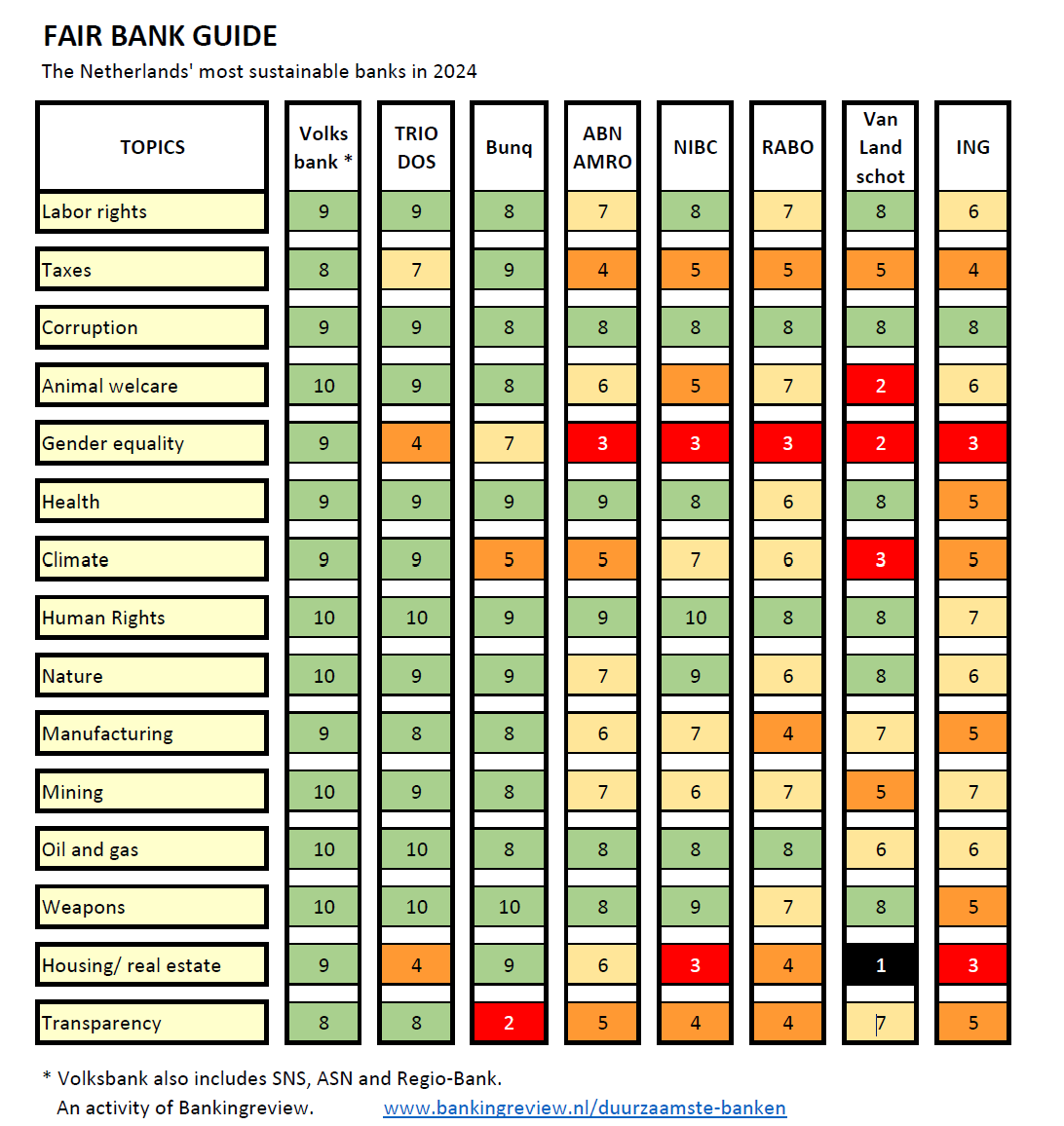

We bank sustainably

Our activities are financed by SNS Bank, part of De Volksbank. This bank believes that sustainability is very important. They do not invest in activities relating to armaments, fossil fuel or intensive agriculture. Every new customer is assessed on their sustainability and must comply with their conditions. Including us. See also: www.devolksbank.nl/en/about-us

We insure sustainably

We examined the policies of insurance companies. It is important to us where they invest our money and what criteria they thereby apply. Ultimately we opted for ASR Insurance, although there is still room for improvement even with them. What is noteworthy is that despite their principles, the charges for their products are in line with the market.

Pieter Pot

Pieter Pot is an online supermarket that only supplies products in reusable packaging. Van der Sar Import buys as many products as possible from this appealing business. See also: www.pieter-pot.nl (only Dutch language)

We develop sustainably

We regularly develop new pots and baskets. For this, we always seek out new materials. We are only interested in materials that have little or no impact on the environment.

Where possible, environmental certificates form part of our requirements for the product and production process. Many materials do not yet have environmental certificates. In that case we assess the environmental impact ourselves. Our knowledge in this area is growing rapidly. We are thereby transparent and communicate our findings.

Suppliers are partly selected on the basis of sustainability and corporate social responsibility. We regularly visit the production facilities and also check the working conditions under which our products are made.

We have certified our rattan production

The showcase and trailblazer within our sustainable range is our rattan factory in Indonesia. We have been harvesting rattan sustainably in the rainforests of Indonesia for years. This means that no tropical rainforest is sacrificed for the production of our baskets. We were the first in the world (!) to receive a certificate for our sustainable production process (March 2022).

It goes without saying that the certificate also requires us to have a socially responsible employment policy. In our rattan factory employees receive a fair salary, free coffee, a freshly cooked meal every day, their own bank account, a contract of employment and health insurance.

Following rattan we are also keen to certify the other product groups. Our products made of seagrass, jute and recycled cotton are already manufactured sustainably. For more information about our sustainable products visit www.terima-kasih.nl/en/home-eng/

Not everything is sustainable yet

The important product group of ceramic pots is still manufactured in the traditional way. This production requires a lot of energy. These complex processes cannot be modified overnight. We regularly discuss this topic with our suppliers, but we are not anticipating a sustainable solution here in the near future. The path to 100% sustainability is a long one, along which we seek to progress every day.

Our sustainable way of working and thinking demands extra effort from our organisation. We do this because we think it’s important. Luckily most customers appreciate our commitment. That gives us the motivation to continue on this path.